Have you ever felt constrained by the speed of your tools when it comes to designing? Most designers feel a disconnect between thought and action when constructing complicated constructions or ultra-large models. The need to have quicker turnaround, more stable and hands-free calibration is on the increase as more creative disciplines implement more sophisticated digital fabrication processes. Be it the testing of functional prototype designs, or the polishing of complex designs, the demand of quality, fast-speed machinery has become a hallmark in the current working environment.

The other problem arises, however, as more makers make more ambitious projects, they need to be able to optimize the time spent not only to be precise but also to be scaled. The bigger models are more commonly known to take longer build times which may slow the process and inhibit creativity. The introduction of the next generation machines that are fast, better structured, and automated set up has radically altered the achievements of what can be done on the desktop. Such a transformation gives the creators with higher performance goals and less aggressive learning curve a chance.

Expanding Opportunities With Smarter, Faster Tools

The innovation in this category is based on two key improvements, which are automation and motion system engineering. Newly refined architectures enable quick and constant movement without use of manual effort, optimization of consistency in automated calibration and reduction of manual efforts, print quality remains the same even at extreme velocity. Consequently, designers have more liberty to work with ideas and less about mechanical changes an ideal combination to any designer who would want to simplify the designing processes.

CREALITY STORE

Rooted in accessible innovation, CREALITY STORE has built a strong reputation for providing solutions that elevate creative workflows. Its machines serve as stepping stones for hobbyists, educators, and professionals seeking a dependable platform. By consistently developing refined structures, intelligent calibration systems, and high-performance motion designs, the brand supports anyone aiming to turn an idea into a functional model with ease and speed.

Reimagining Performance Potential

The invention of structural engineering has contributed significantly to performance in the category. Stiffened frames, enhanced movement trajectories, and enhanced extruder modules all result in high productivity despite high speeds. Automated functions save more time on setup and make the process of initiation to completion easy.

- Optimized architecture for enhanced motion stability

- Enhanced calibration systems that reduce human error

Such capabilities will be outstanding to any person seeking to venture into high-speed production without quality being affected. Their combination leads to convenience, precision, and reliability, which makes the whole process less problematic. To understand these machines better, the following paragraphs discuss single models that are aimed at promoting creativity based on different demands.

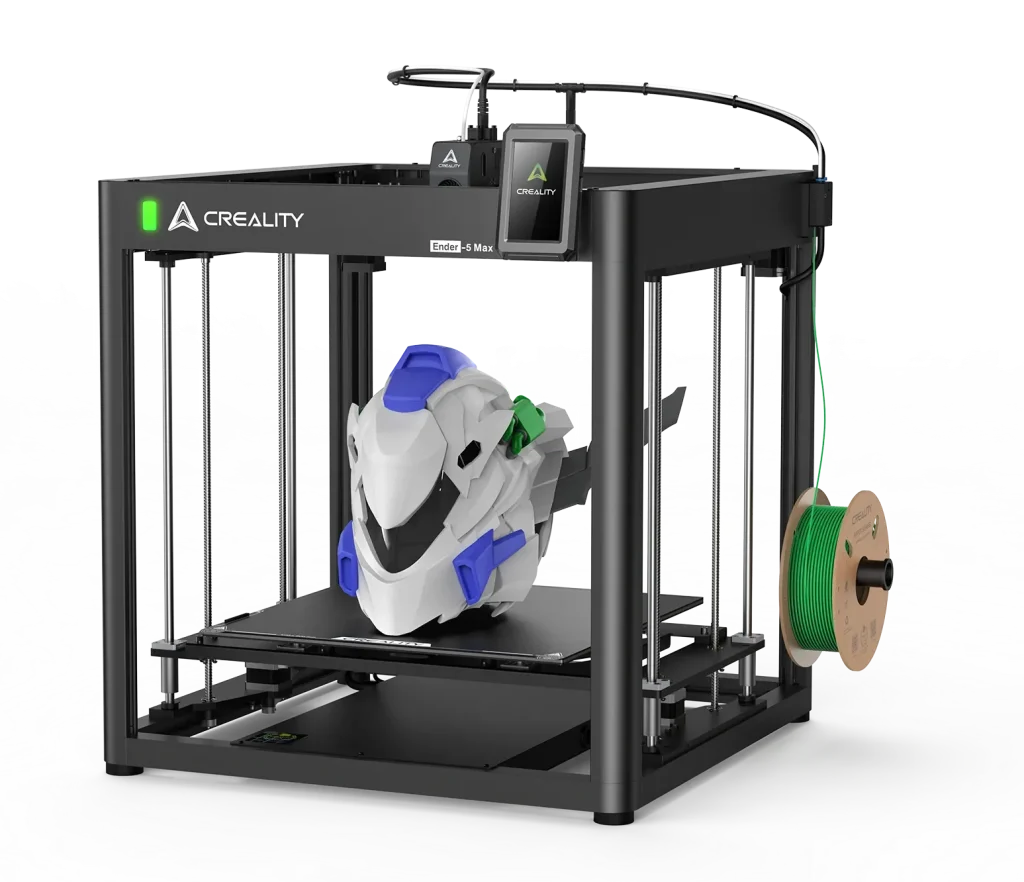

Ender-5 Max 3D Printer

The Ender-5 Max 3D Printer has a stunning ratio of structure, scale and performance which can be used in large-format printing. The frame is made of pure metal and it is stiff, which results in greater stability, allowing the frame to perform consistently throughout a long period. It has a 64-point automatic leveling that intelligently scans the build surface, which reduces tissue hand adjustment and eliminates variation in the results. Reaching speeds of up to 700 mm/s increases productivity, particularly useful in professional processes or multi-piece assembly that needs rapid prototyping. It has ample 400 mm cubed work space where oversized models, architectural work and working assemblies, which enjoy gaps in construction, can be left.

The other positive thing about the Ender-5 Max 3D Printer is that it is appropriate in a multi-unit setting because of the WLAN connection and built-in status lighting. This simplifies the management of multiple machines particularly in the settings that require sustained production. A non-obligatory enclosure will aid in enhancing high ambient temperature of specialized engineering materials, and they will be stable during the extrusion by extended cycles. The set of these features aids creators who want to use an efficient and scalable solution to large-format design.

- 64-point automated calibration

- 700 mm/s top-tier speed for fast builds

- 400 mm³ large working envelope

Get started with the Ender-5 Max 3D Printer today!

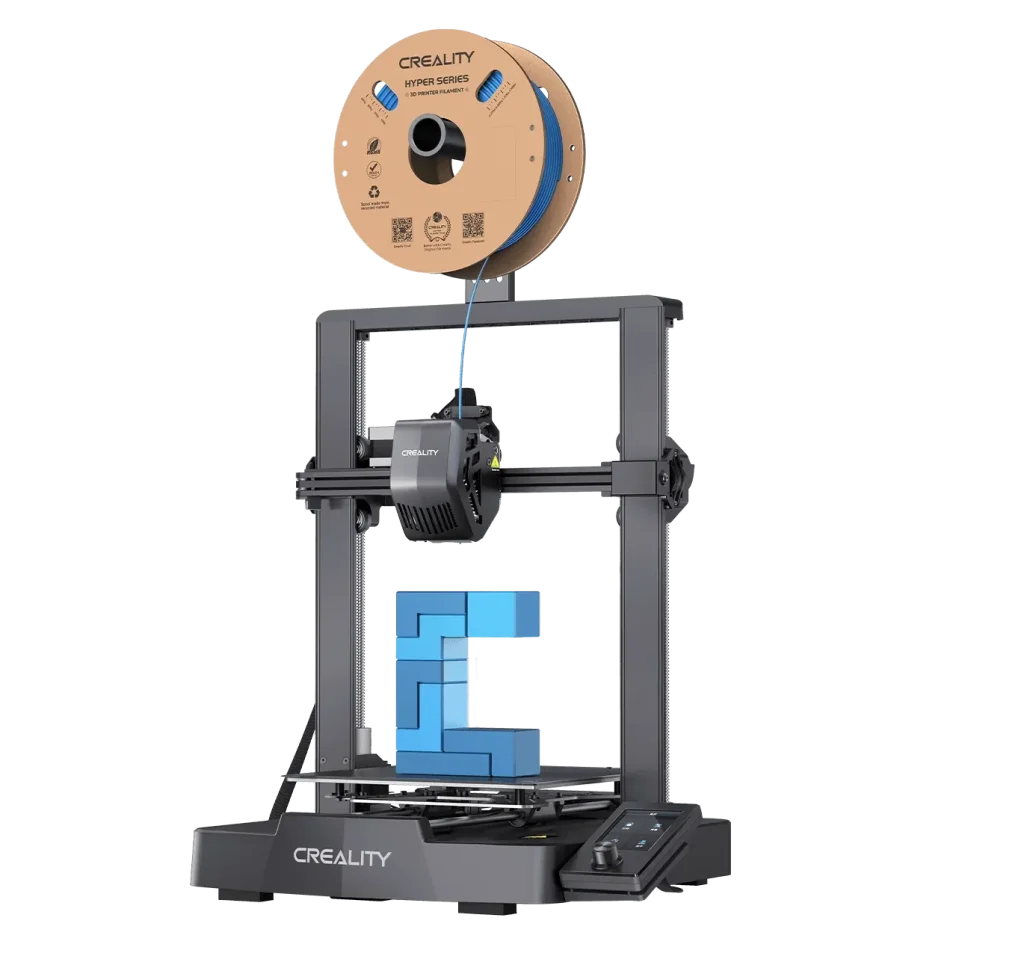

Ender-3 V3 SE 3D Printer

The Ender-3 V3 SE 3D Printer presents a small but fully functional choice to imaginative individuals who want better quality. Having a top speed of 250 mm/s and acceleration of up to 2500 mm/s 2, it can be used in rapid prototyping as well as produce accurate results. It has CR Touch and strain-based sensors that allow the machine to automatically make leveling and Z-offset corrections, simplifying the setup process to both beginners and professionals. An optional, direct extruder is used to enhance its via-capability to work with such materials as PLA, PETG, and flexible TPU with a steady feed.

The Y-axis has dual stabilization and the dual linear shafts that provide a solid foundation to the movement both vertical and horizontal. This assists in decreasing the wobbling and offers a more efficient general action particularly when constructing taller constructions. All the automatic loading and unloading opportunities ease the process of managing the materials and maintain the flow of the work process without additional hands-on interruptions.

- 250 mm/s max speed

- Automated leveling with CR Touch and strain sensors

- “Sprite” direct extrusion with wide material support

Bring home the Ender-3 V3 SE 3D Printer now!

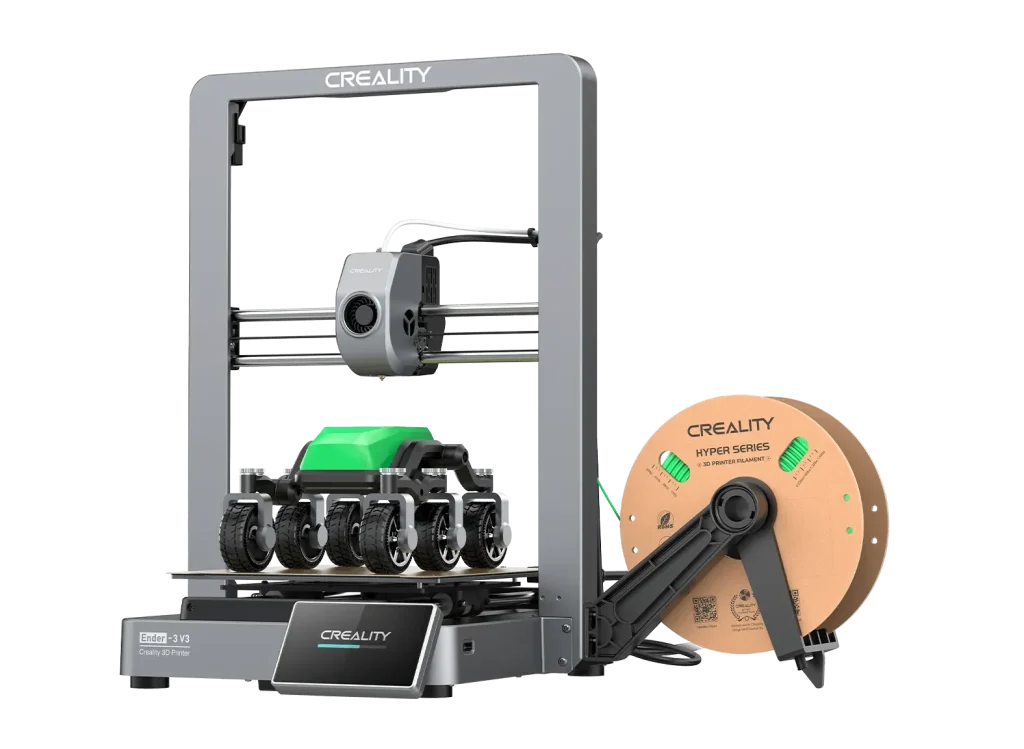

Ender-3 V3 3D Printer

The Ender-3 V3 3D Printer offers a performance-based architecture, which is based on CoreXZ system, with a maximum speed of 600 mm/s. In this engineering process, weight to be moved on the parts is minimized and it can travel faster and cleaner with remarkable accuracy. Die-cast metal structure offers a greater level of rigidity which reduces vibration and allows operation at high speed. It can utilize its full-power direct extrusion system which is capable of controlled and consistent flow of material resulting to better print quality of small and finer features.

The other useful characteristic of the Ender-3 V3 3D Printer is that it has an inbuilt tri-metal nozzle that is durable and can be easily replaced once it wears. Dual fans make the cooling quicker and assist in creating clean edges and sharpened surfaces even at higher speeds. Auto-calibration capabilities make the setup easier, and the system is useful in aligning the entire process of building, which improves on the experience of users who implement tasks that require time and demands.

- CoreXZ architecture for rapid movement

- Rigid die-cast structure

- Full-power direct extrusion

Upgrade your workspace with the Ender-3 V3 3D Printer today!

Ender-3 V3 Plus 3D Printer

The Ender-3 V3 Plus 3D Printer expands creative room with its 300×300×330 mm build space, ideal for larger models and functional prototypes. Its heavy-duty construction features dual motors and support rods on the Y-axis, giving the machine exceptional stability for long and tall builds. While supporting CoreXZ motion for speeds up to 600 mm/s, it maintains structural strength that ensures consistent layering throughout extended prints. The extruder system is optimized to reduce clogging, keeping material flow smooth and reliable.

A quick-swap tri-metal nozzle allows easy maintenance and rapid changes, supporting uninterrupted workflow during back-to-back tasks. Dual cooling fans accelerate solidification of freshly laid material, enhancing surface detail at higher speeds. Access to premium cloud features for one year offers additional models, cloud storage, and fast download options that support experimentation and productivity.

- Large 300×300×330 mm build area

- Y-axis dual motors and support rods

- High-speed CoreXZ performance

Power your ideas with the Ender-3 V3 Plus 3D Printer!

Ender-3 V3 KE 3D Printer

The Ender-3 V3 KE 3D Printer stands out through its combination of speed, temperature capacity, and intelligent operation. With up to 500 mm/s speed and 8000 mm/s² acceleration, it enables exceptionally rapid builds without losing consistency. A “Sprite” direct extruder supports temperatures up to 300°C, giving flexibility for a wide range of materials, including PLA, PETG, ABS, ASA, and TPU. Linear rail support on the X-axis boosts smooth, precise movement, making the overall operation more refined.

This machine also provides multiple connectivity methods, including phone control, WiFi, and USB, bringing convenience to different workflow styles. Quick assembly, self-testing, and automatic filament loading reduce preparation time, allowing users to jump into new tasks sooner. These features collectively offer a modern, high-efficiency tool suitable for fast and versatile creation.

- 500 mm/s high-speed capability

- 300°C material-ready direct extrusion

- X-axis linear rail system

Experience next-level speed with the Ender-3 V3 KE 3D Printer!

Shaping the Future of Personal Fabrication

As modern creative work continues to evolve, adaptable machines are playing a more significant role than ever. Rising expectations for precision, speed, and automation have reshaped what a desktop system can deliver. With improved motion systems, smarter calibration features, and thoughtfully engineered structures, creators now enjoy more fluid and confident workflows.

Advancements across this series show how engineering and accessibility can coexist. Each model supports different needs: some excel in large-format builds, others in compact efficiency or specialized material handling. This variety allows creators to align their tools with their vision, making the process both enjoyable and seamless.

Begin your creative journey with a high-performance solution today!